What are the Benefits of Cooling Tower Efficiency?: How the Right Cooling Tower Valves and Screens Can Help

June 27, 2023

What is a Traveling Water Screen?

September 29, 2023Cooling towers are driven by water. Just like any river, creek, or stream, this water flow is powerful. The Colorado River created the Grand Canyon over centuries.

It achieved this simply by flowing. As water moves through a cooling tower system, it can wreak havoc on the different components, apparatuses, and systems within the tower. The turbulence created by this constant flow that powers the cooling tower can create excessive wear and tear. The right cooling tower valve can prevent this damage keep cooling tower systems optimized and efficient.

What is Chattering in a Cooling Tower?

Conventional distribution valves inside of a cooling tower tend to experience excessive wear from the water’s movement through the system. This process creates what’s known as “chattering.” Chattering occurs when the stem and disc in the valve move due to the water’s turbulence. The more consistently this happens, the sooner these valves need to be replaced.

Repairing and replacing valves carries expensive consequences. First and foremost is the downtime and resources needed to perform this maintenance. There is also the hard cost of replacing these components and the manpower that could be used elsewhere for more productive tasks. However, chattering can be eliminated with a cooling tower valve designed, engineered, and constructed to stand up against the force of water.

Cooling Tower Valve Materials and Design

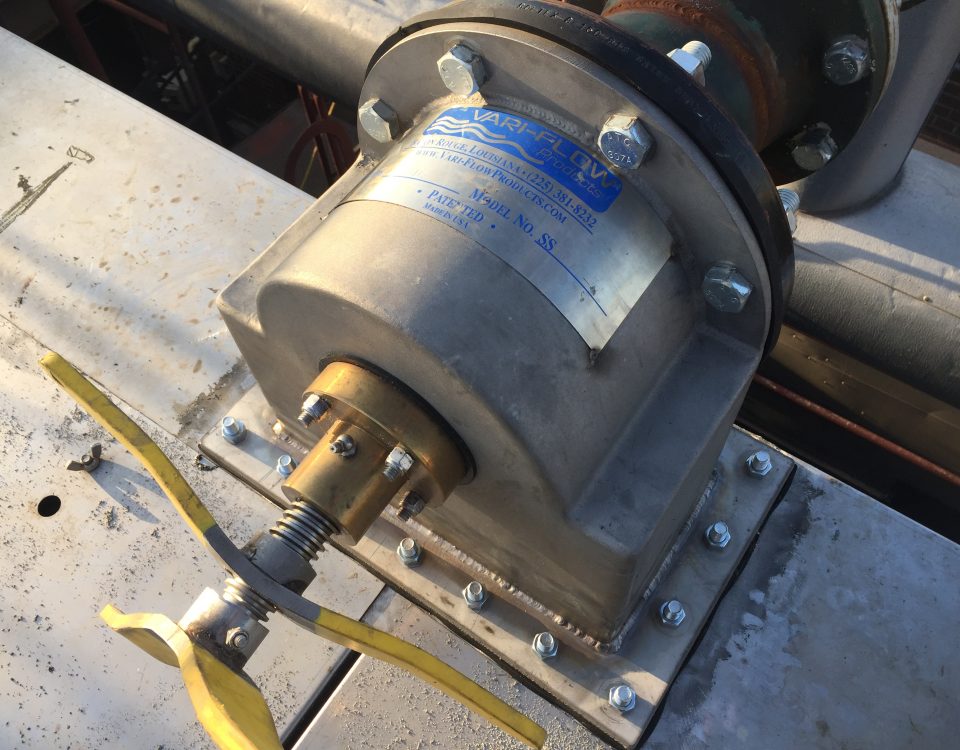

With the best engineering and materials, the water can be balanced as it flows through the cooling tower. Vari-Flow valves are built from a combination of a stainless steel stem and UHMW-PE plastic bushing that requires no grease or other maintenance. These valves also feature an internal guide system that supports it for its entire length of travel, balancing the water for a smooth transition.

Cooling tower valves can make all of the difference, not only for your facility’s performance but in mitigating the costly tasks of maintaining and repairing its infrastructure. Cooling Tower Valves and Screens LLC and their Vari-Flow valve and screen products can save your operations time and money.