Industrial Cooling Tower Screen Repair: Reducing Maintenance Costs

April 25, 2023

Stationary Screens: Enhancing Your Cooling Tower’s Performance

June 27, 2023Traveling water or traveling sump screens are ideal for facilities looking to reduce or eliminate the cost and resource expenditure for maintenance, cleaning, and replacement that static water screens require. Traveling water screens have long been regarded as an effective, efficient, low-maintenance option.

How Do Traveling Cooling Tower Screens Work?

This type of filter gets its name because these screens rotate through motor operation with a timing mechanism. This “traveling” allows them to be cleaned and cleared periodically. Due to this self-cleaning automation, little to no involvement from a plant or facility’s personnel is needed. This means that you can apply your resources elsewhere to improve further and grow your operation.

What Should Be Considered When Selecting a Cooling Tower Screen?

Not all cooling towers are the same. While they are designed to perform the same task, but the environment, conditions, size, and scope of their operation vary from place to place. Nevertheless, the performance of your cooling tower will be dependent upon who well its water screen performs. The type of screen you opt for should account for these variables:

- The size of the expected debris and other material that the screen will capture

- The overall amount of debris that is anticipated to pass through your cooling tower system

- Your available resources and workforce for cleaning, maintenance, repairs, and replacement

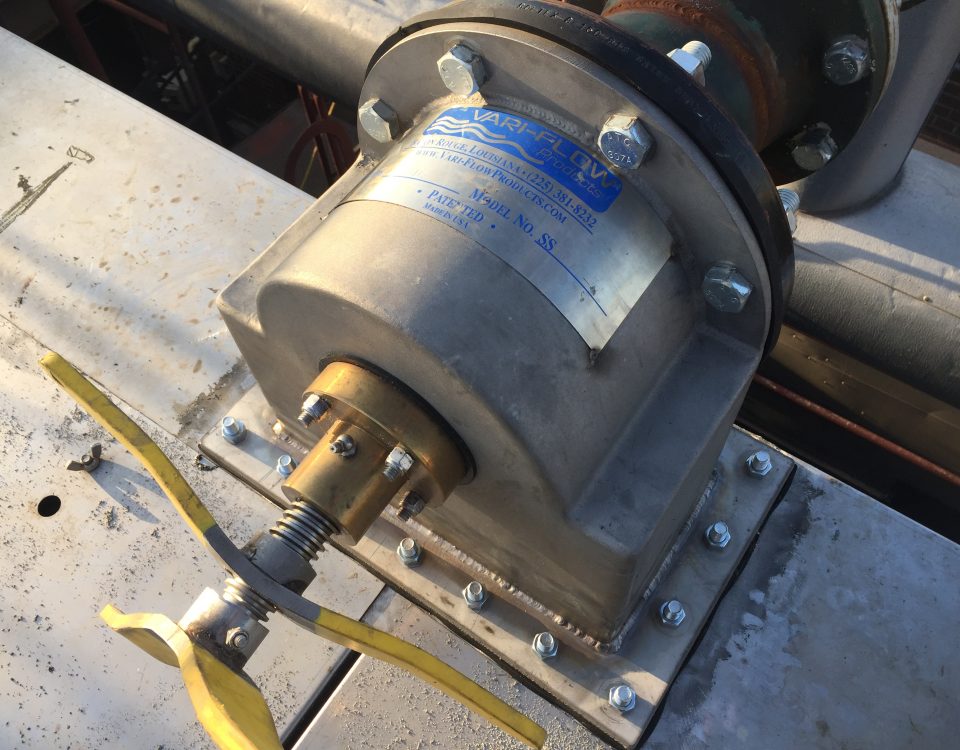

Why are Vari-Flow Screens the Superior Cooling Tower Screen Option?

Vari-Flow cooling tower screens can handle the first two considerations and resolve the need for the third. These highly engineered screens are designed to keep exchangers free of debris, eliminate the need for screens to be removed for cleaning, and offer a simple “back flush” system that only requires one operator to clean the screen in a matter of minutes.

Vari-Flows offers a full line of cooling towers valves and screens that reduce your overall costs of operation while mitigating the risk of making expensive repairs and replacements and ending the need for costly downtime.