Cooling Tower Float Valves: How They Work and Why They Matter

August 26, 2025

Cooling Tower Valves & Screens in the Gulf Coast: Fighting Corrosion with the Right Materials

September 26, 2025Cooling tower valves are essential for regulating water flow, protecting system efficiency, and minimizing costly downtime. The material used in these valves has a direct impact on durability, maintenance needs, and long-term performance. Across the industry, two of the most common options are stainless steel and UHMW-PE (Ultra High Molecular Weight Polyethylene). Each material brings unique advantages, but both also have limitations that facility managers must consider.

Corrosion Resistance of Stainless Steel and UHMW-PE Cooling Tower Valves

Valves are continuously exposed to water and chemical treatments, making corrosion resistance a critical factor.

Stainless Steel – Grades like 304L and 316L provide excellent protection in moderately aggressive environments, but under heavy chemical exposure, even stainless steel is vulnerable and requires ongoing inspection.

UHMW-PE – This material is immune to rust and highly resistant to chemical attack, making it a strong choice where corrosion is a primary concern.

Both materials help extend valve lifespan, but on their own, each can run into challenges under extreme operating conditions.

Maintenance Requirements for Stainless Steel and UHMW-PE Valves

Maintenance requirements are another deciding factor in valve selection. Stainless steel valves, while durable, require regular lubrication and monitoring to prevent wear and corrosion over time. Their heavier components can also increase the risk of mechanical wear if not maintained properly. In contrast, UHMW-PE valves are self-lubricating and abrasion-resistant, reducing the need for greasing and routine intervention.

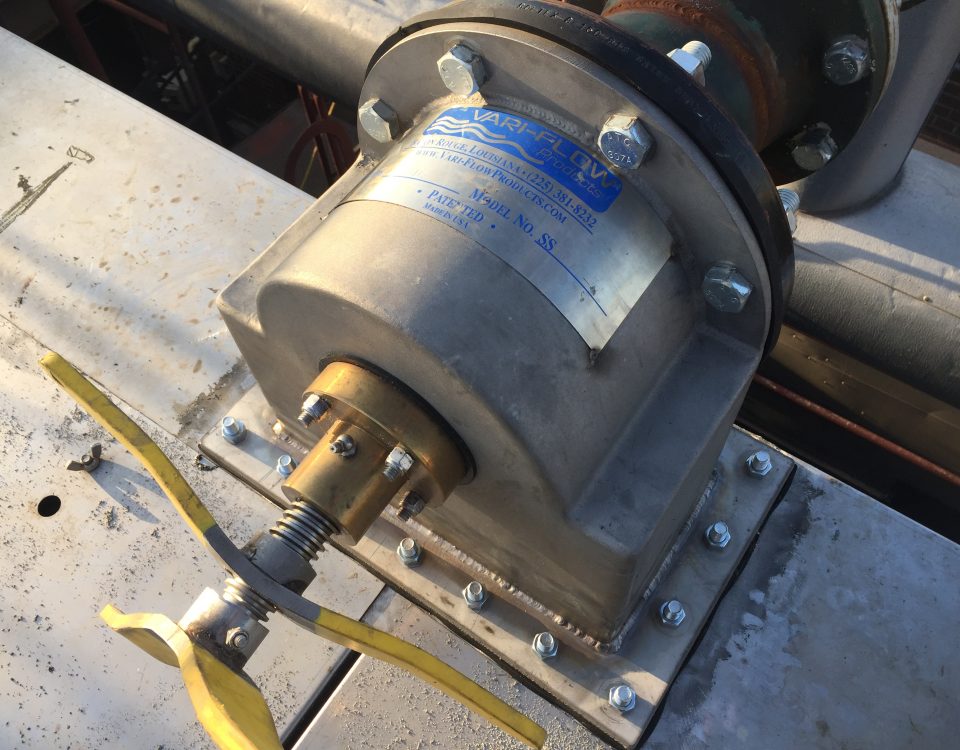

The Vari-Flow valve pairs a stainless-steel stem with a UHMW-PE bushing, eliminating the need for greasing while reducing long-term maintenance. This hybrid approach simplifies upkeep while delivering extended service life.

Comparing Stainless Steel and UHMW-PE Cooling Tower Valves

The mechanical properties and cost of valve materials both affect overall system performance and long-term value.

Stainless Steel – Strong, heat-resistant, and capable of handling heavy loads. Its durability makes it ideal for demanding applications, but its heavier weight can increase installation difficulty and mechanical wear. Stainless steel valves also tend to have a higher upfront cost, though they provide excellent high-temperature tolerance.

UHMW-PE – Lightweight, abrasion-resistant, and self-lubricating, UHMW-PE reduces overall valve weight and improves water flow efficiency. It is also more affordable and requires less maintenance, although its mechanical strength is lower than that of stainless steel.

Individually, each material has trade-offs. By combining the benefits of both, CTVS’s Vari-Flow valve improves performance, reduces maintenance, and extends valve life.

Why Hybrid Cooling Tower Valves Are the Preferred Choice

While many systems utilize valves made entirely of stainless steel or UHMW-PE, innovative hybrid designs are setting a new standard for performance. By pairing a stainless-steel stem with a UHMW-PE bushing, valves like the Vari-Flow deliver:

- Structural strength and durability of stainless steel

- Corrosion resistance and low maintenance of UHMW-PE

- Smoother operation with no greasing required

- Improved sealing performance with advanced gasket and guide systems

This internal guide system supports the stem and disc throughout its full travel, while the enhanced gasket design ensures complete shut-off and eliminates the persistent leaking often associated with conventional valves. These engineering improvements provide a reliable balance of strength, efficiency, and maintenance-free operation.

With CTVS’s Vari-Flow valve, facilities can reduce maintenance, minimize downtime, and improve cooling tower efficiency for long-term reliability.